Ford Invests In America’s 1st Lithium Iron Phosphate Battery Plant

Lithium Iron Phosphate (LFP) batteries will be made by Ford in the USA for their EVs.

Ford Motor Company has announced that it will be investing US$3.5 billion to construct America’s first automaker-backed LFP battery plant. The company will establish the BlueOval Battery Park Michigan, which will begin producing LFP batteries in 2026 and will initially employ 2,500 people. The new facility will be part of a wholly-owned Ford subsidiary, and the automaker will have the option to expand its battery capacity at its Marshall, Michigan, plant. This announcement is part of Ford’s US$17.6 billion investment in electric vehicle and battery production in the United States since 2019, as it commits to invest more than US$50 billion in electric vehicles globally through 2026.

With this new LFP battery plant, Ford will diversify and localise its battery supply chain to improve availability and affordability for its customers while strengthening consumer demand. This investment will result in the creation of more than 18,000 direct jobs in Michigan, Kentucky, Tennessee, Ohio and Missouri over the next three years and more than 100,000 indirect jobs, according to an independent study.

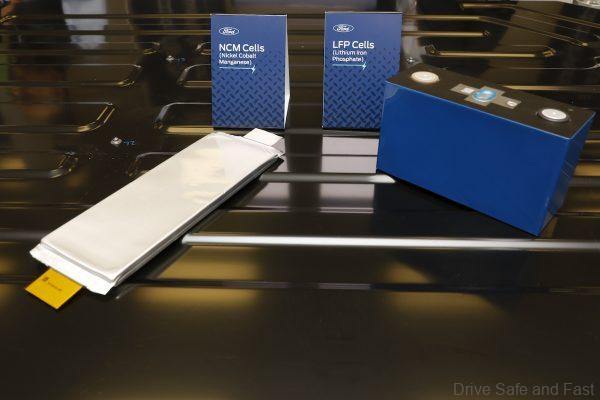

Ford’s LFP batteries will complement its existing battery technology, nickel cobalt manganese (NCM). Offering LFP batteries will enable Ford customers to choose an electric vehicle with battery performance characteristics that align with their needs.

LFP batteries are durable and can tolerate more frequent and faster charging while using fewer high-demand and high-cost materials. This lower-cost battery will help Ford contain or even further reduce EV prices for its customers while supporting the automaker’s goal of an 8% EBIT margin for Model e by 2026.

Ford President and CEO, Jim Farley, said, “Ford’s electric vehicle lineup has generated huge demand. To get as many Ford EVs to customers as possible, we’re the first automaker to commit to build both NCM and LFP batteries in the United States. We’re delivering on our commitments as we scale LFP and NCM batteries, and thousands, and soon millions, of customers will begin to reap the benefits of Ford EVs with cutting-edge, durable battery technologies that are growing more affordable over time.”

In addition to the LFP battery plant, Ford will introduce LFP batteries on Mustang Mach-E this year and F-150 Lightning in 2024 to increase production capacity and reduce wait times for customers.

Ford’s decision to invest in the LFP battery plant comes as the company rapidly scales up EV production, working towards delivering an annual run rate of 600,000 electric vehicles globally by the end of this year and 2 million globally by the end of 2026, as part of its Ford+ plan. As the global demand for electric vehicles increases, automakers are investing heavily in new battery technologies, and Ford’s LFP battery plant is a significant step in achieving a sustainable future for the automotive industry.