Here’s How Jaguar Land Rover Protects Factory Workers

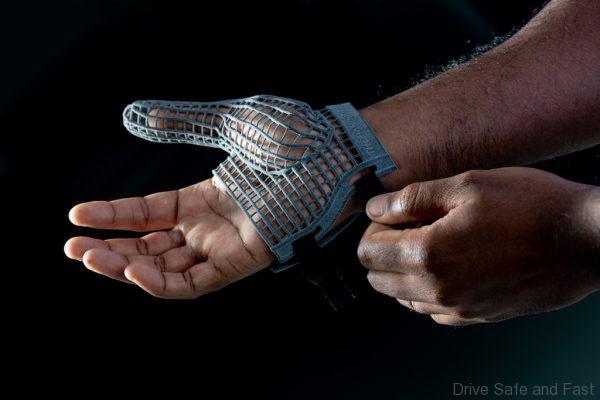

Working repetitive jobs like attaching clips and fasteners to a chassis can result in musculoskeletal disorders. In fact, this kind of injury makes up 30% of all workplace injuries. More importantly, a third of the money paid by Jaguar Land Rover as compensation to employees stems from these injuries. Which is probably why they’ve commissioned a new lightweight 3D-printed glove to protect employees from musculoskeletal disorders.

The glove has been been designed to reduce muscle fatigue by being supportive yet comfortable to wear throughout the typical 8 hour shift.

Following feedback from trials, a 2nd generation of the glove is being developed with a foam pad from impact additive D30. This ought to protect the palms of those who install parts like door casings.

The Jaguar Land Rover Additive Manufacturing Centre produces over 80,000 parts a year for a variety of applications, including functional prototyping, design mock-ups and manufacturing assembly aids and fixtures. Jaguar Land Rover is also able to 3D print parts for production cars with the Jaguar XE SV Project 8 one of the first vehicles to use them.

The programme forms part of Jaguar Land Rover’s Destination Zero vision; an ambition to make societies safer and healthier, and the environment cleaner. Delivered through relentless innovation, the company’s focus is on achieving a future of zero emissions, zero accidents and zero congestion – across its facilities, and through its products and services.